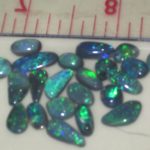

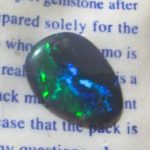

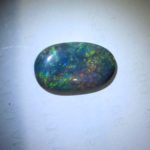

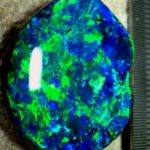

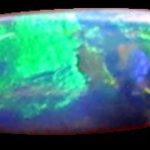

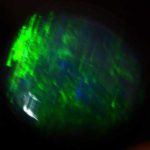

Polished opals Australian gemstone package.

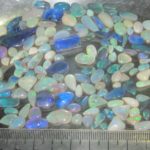

Polished opals direct from Graham’s Heritage mine is safer then buying and cutting polishing opals, because this very specialized skill. Rough opal in uncut state is purchased often from the middlemen or sometimes direct from the primary producer miners. Specialized skill dealers sort through the rough parcels direct from the opal mines, hopefully professionally predicting the value of gemstones which can be cut polished from the rough stones. The only way to guarantee you’re buying direct is to go to the mining towns, it’s better not to buy in town because often they are middlemen again based in town. You have to go out of town direct to the mining fields, then hopefully find someone that is finding something,and has rough and has not already been to the cutters and had there rough polished.

Polished opals Australian gemstone package.

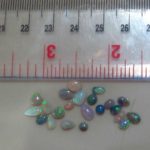

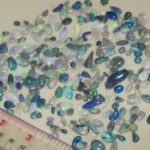

But there is never any guarantee as cutting and the final polishing can produce very different unpredictable outcomes every time unless you have many years of experience. This is why I recommend starting with purchasing finish polished opals, and then maybe moving into rubs and get a very good look at rubs before buying rough.

The opal cutter sorts through the rough material parcel and decided which color pieces of rough are worth cutting, than to the diamond saw cut the rough opal into desired sizes, the next stage will bring you closer to the rubs. Any excess grey black or white colors material plus cracks and potch is cut off and discarded, the rough opal is cut into a basic stone shape, you are now getting close to the rub stage.

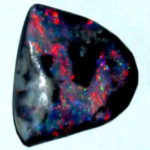

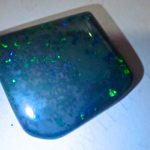

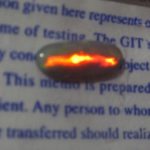

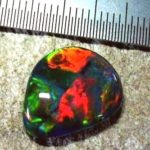

Australian Queensland boulder opal can be much more difficult to cut as it forms in tiny cavities in the ironstone, but often very thin colour veins, ironstone is generally left to support the finished gemstone and the back of the stone is often orange to brown colour. Ironstone is also harder than crystal opal black or white opal which is about as hard as glass. Opal will cut away a lot faster quicker than ironstone, extra care must be taken with Australian Queensland boulder Opal.

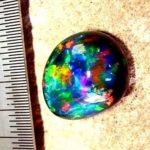

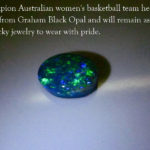

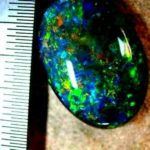

Basic concept for all cutters they always need to think about keeping the colors of the opals as much as possible and size as big as possible, making sure of little waste and maximizing the size of the gemstone. Always work slow even during the final polishing, or small pits can form on the face of the surface of the stone forcing the final value down,because the final smooth surface and polish has been interfered with because of heat .Every rotation moment when cutting reduces the size of the gemstone, maximum concentration control must be exercised. Never forget do not allowed to much heat as opal can be burned and may crack if subjected to high temperatures. Always check your water never get lazy, water must always be used when cutting opal to avoid cracking due to cutters heating the stone for too long, leaving the stone in one place even with plenty of water can damage a stone.

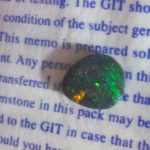

Polished opals Australian gemstone package.

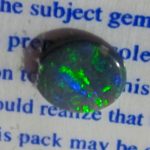

Now that you have completed these steps the stone has been cut down by the diamond saw, the cutter will place the opals on to wooden dob sticks, lengths of wood doweling with heated wax to adhere the gemstone to the end of the stick. Now the cutter has control which will allow a greater degree of workmanship with the next step the wheel. Stick the face up which will be the best color of the stone pointing upwards and consider the best shape for the gemstone also. But this varies a lot between first world countries and developing countries such as India China, many inclusions will be left in the face in developing and Third World countries. First world countries the shapes will be a lot smaller and or inclusions removed.

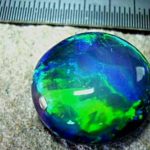

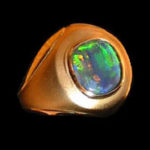

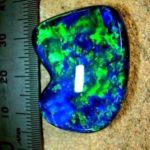

The cutter will then step down to finder coarse different diamond grinding wheels, shaping and facing more color getting closer to the perfect gemstone. You must start removing imperfections sand grey and black spots, why removing saw marks from previous stages. Start working on the high dome into a cabochon shape, oval oblong are often preferred shapes, but always keep in mind to keep the size as big as possible. Okay we are getting close to the final stage for the finish opal face polishing. Serum Oxide a good polishing agent on a felt wheel with water will give the gemstone are very good polish. If you are happy and you cannot see any more grinding marks, then simply removes the finished opal, place and stick the gemstone back on the wax with the back of the gemstone facing the opposite direction this time up.

You must consider the back of the gemstone flat bottom for the gemstone, and an edge with tapers maybe depending on your market. Some wholesalers do not care a lot about the bottom and leave this edge up to the jewelers to set the back of the stone, that will be underneath the silver or gold and only the polished opals will be visible to the naked eye.